In the high-quality development of the battery industry, product stability is of utmost importance . As a professional lithium battery manufacturer and lithium battery supplier(covering KION Lithium Batteries and other types of lithium batteries), we not only conduct basic aging tests (to verify long-term performance), but also add a crucial joint debugging step in the workflow to emphasize our strict quality control of lithium-ion battery solutions and vehicle-mounted lithium-ion batteries.

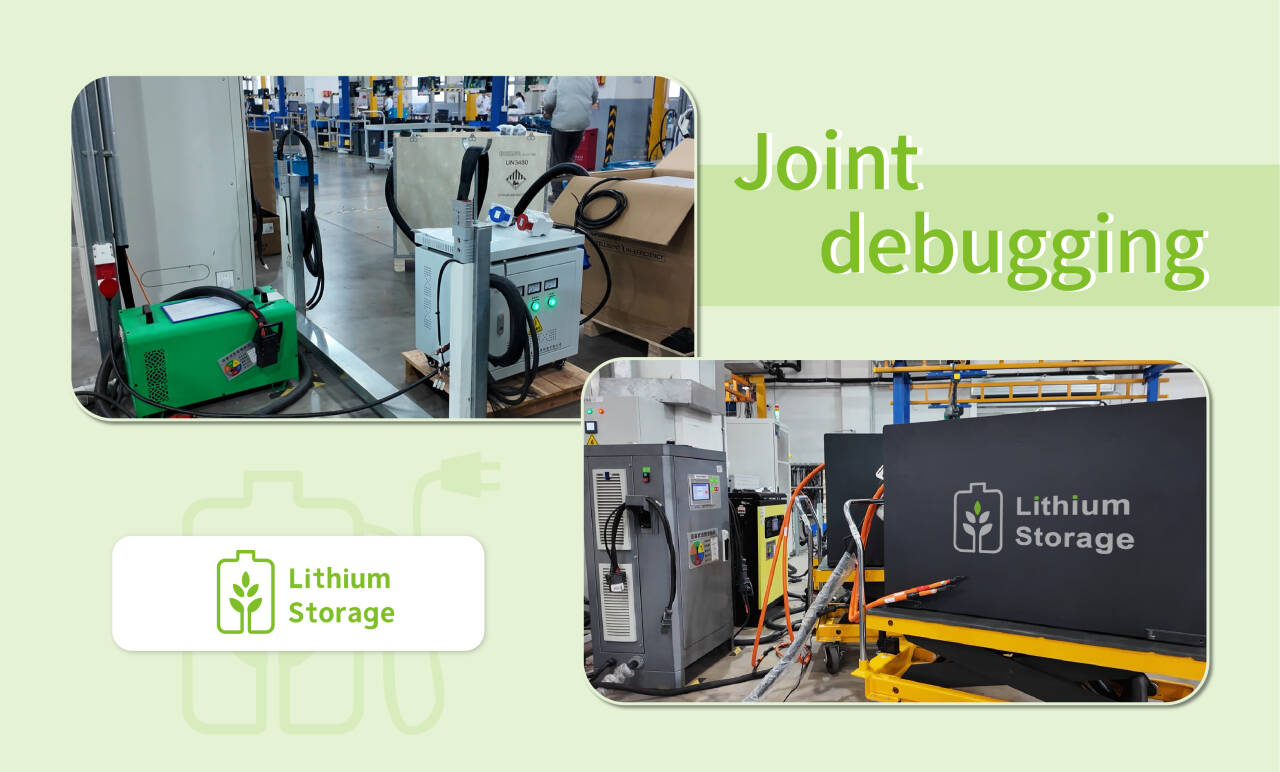

After assembly (such as forklift lithium battery packs) and routine aging tests, the battery packs will enter our joint debugging workshop. As a lithium-ion battery China manufacturer, we follow strict procedures: We connect the battery packs to their matching chargers and built-in dashboards, establishing a bidirectional data channel to monitor real-time interaction.

During the debugging process, the core task is to compare the key parameters (current, voltage, and frequency) of the charger output end and the receiving end of the battery pack (through the dashboard). This process follows the CE standard and is consistent with the actual operating conditions of the forklift lithium battery units. If the difference between the parameters on both sides exceeds the preset threshold, it is judged as abnormal.

To diagnose such abnormal situations, we adopt targeted troubleshooting methods:

Line current clamp testing: Using professional clamp current meters to measure the current of a single cable without cutting the circuit, discovering issues such as poor line contact or abnormal resistance.

CAN bus message capture: Using dedicated diagnostic tools to capture communication messages between the charger, dashboard, and BMS, and parsing protocol data to detect faults such as signal interference, data packet loss, or abnormal command responses (crucial for vehicle-mounted lithium-ion batteries).

Although aging tests lay the foundation for reliability, the joint debugging steps we deliberately take focus on verifying the matching degree of charger and battery parameters - ensuring that no potential risks are overlooked. As a reliable partner for forklift lithium batteries and lithium-ion battery solutions, we will continuously improve these quality-centered processes to provide safe and compatible battery packs for global customers and drive the high-quality development of the industry.