As one of trusted China lithium ion forklift battery companies and manufacturers, Lithium Storage provides a fully customized smart lithium-ion forklift battery adaptable solution for forklifts, including every brand, model, shape, and weight to replace old lead acid battery technology. Our team of engineers can also design bespoke solutions for new product development. Our fully featured customizable lithium battery for forklift solution can retrofit forklift brands including Toyota, Crown, Hyundai, HELI, LINDE, Yale, Mitsubishi, NICHIYU, and Jungheinrich. Our SMART FLT solution improves operational working hours available with a faster charging time and longer life.

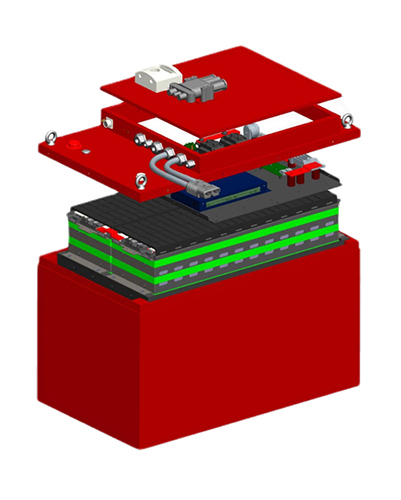

Based on forklift trucks being manufactured in various nonstandard configurations, we select outer box and inner box combination solutions to design our forklift lithium batteries, inter-box for batteries, outer-box for dimension, and additional weight. The advantage of this design is to maximize adapting to more forklift brands and models by using the same inner box. We investigate the battery requirements of many forklift brands on the market, in particular in the dimension and capacity, and summarize 3 model of standard forklift battery products (not including additional weight). Our standard products 25.6V205AH, 41.2V410Ah, and 83.2V410Ah can meet around 80% of forklift requirements in lithium batteries upgraded from lead acid batteries.For saving shipping costs to the international market, Lithium Storage suggests that customers can purchase inner boxes from us, and add weight and outer boxes locally.In the fast-paced world of material handling, the right equipment can make all the difference. Lithium Storage stands out among lithium forklift battery companies, offering cutting-edge solutions designed to elevate your warehouse operations. Let's delve into the unparalleled benefits of Lithium Storage's 36v forklift battery and 24 volt forklift battery for sale.

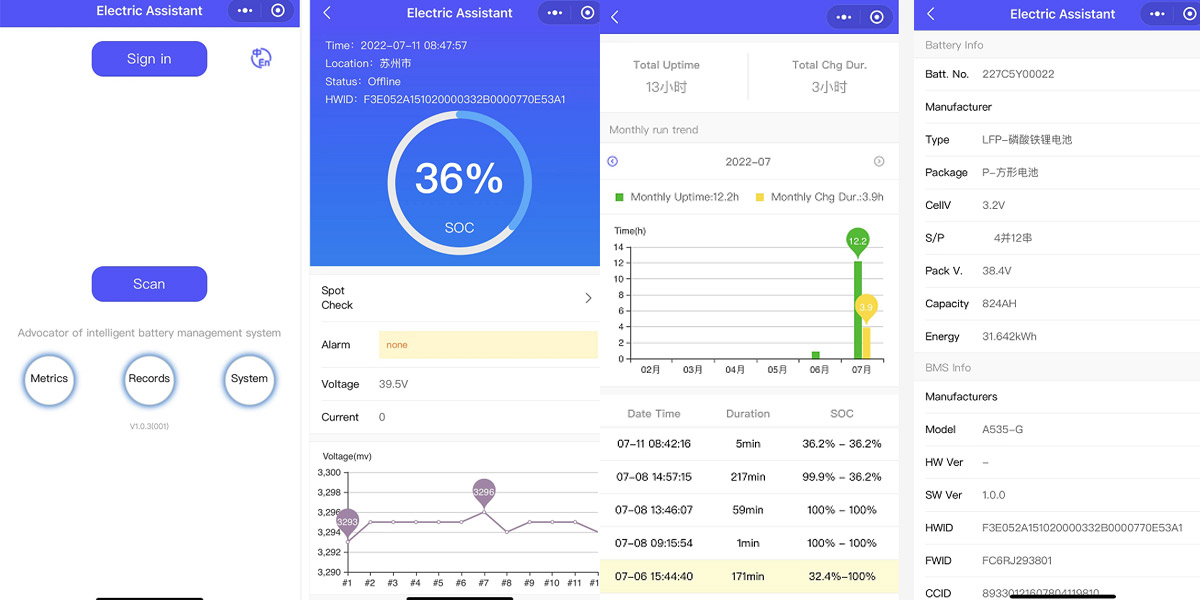

Smart LFT Forklift lithium batteries can be supplied with full cloud interconnection between device terminals to cloud terminals through the wireless data transmission network. LSB Smart LFT battery data cloud platform, seamlessly connected with the BMS intelligent terminal module. Enabling the following monitoring functions online.

Monitor the operation record and status of forklift batteries in real-time

Realize remote alarm and early warning

Trace software and hardware information

Supports the BMS program air upgrade and parameter re-setting

Lithium Storage customers can track the battery information through the device QR code from the following access.

Phone App: Battery Pack Assistant

Applet of WeChat

Web Gate

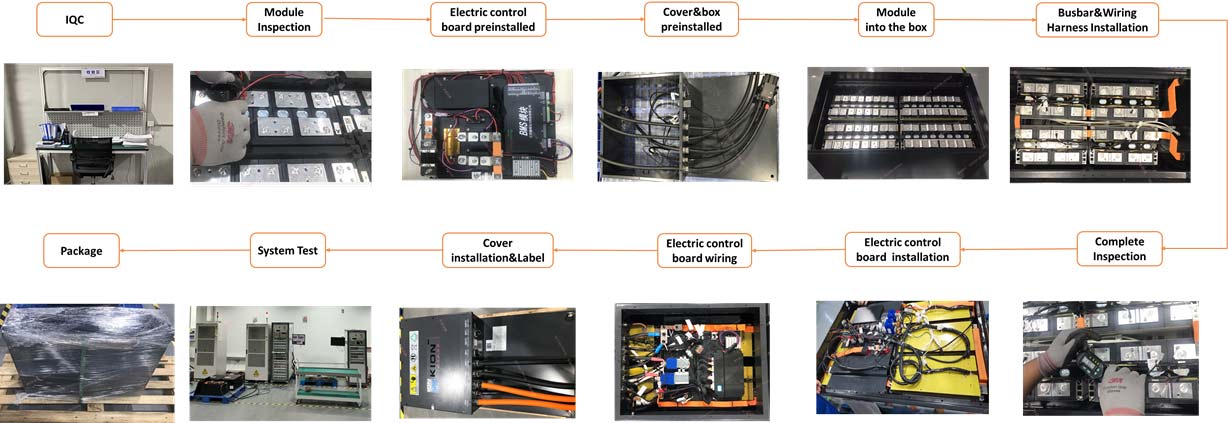

For ensuring the products' delivery quality, Lithium Storage has a series of the standardized production process for forklift lithium batteries, including battery consistency inspection, battery module production, module inspection, electric control board preinstalled, cover&box preinstalled, module into the box, busbar&wiring harness installation, complete inspection, electric control board installation, electric control board wiring, cover installation&lable, system test, and package.

Transition Your Energy to Sustainable Lithium-ion Batteries