Lithium Storage provides standard lithium battery modules and customization of lithium-ion battery modules based on LFP/NCM prismatic lithium cells, including the structure of the banding module and frame welding module. The high structural strength of the frame welding module meets harsh vehicle operating conditions, and the high flexibility of the banding module meets a wide range of dimension requirements.

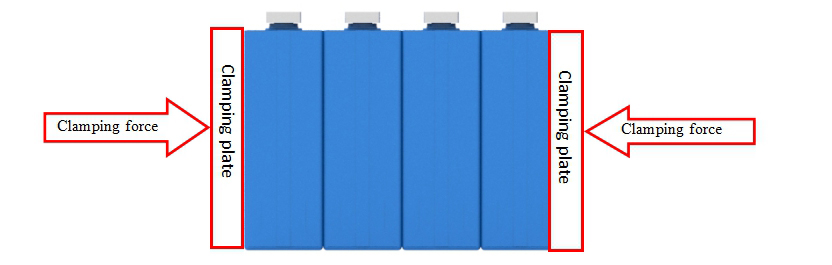

According to the characteristics of aluminum shell batteries, during the life cycle, there will be slightly natural swelling at the center of the large side surface. During assembly of the cells, the customer needs to use a clamping plate to clamp the cells tightly before putting them into the pack enclosure. The recommended clamping force is 150kgf-300kgf for NCM cells and 200kgf-500kgf for LFP cells. (The above is for reference only. For reference to clamping force value, please refer to cell specification for details)

During the cycling of the battery, the cell's internal swell force will increase gradually. At the EOL (end of life) the max internal swell force of the NCM cell will be 2500kgf and the LFP cell will be 2000kgf. The clamping device needs to be strong enough against EOL internal swell force.

| Character | Frame Welding Module | Banding Module |

| Dimension | VDA dimension | Allow custom. The size can be expanded according to the situation due to its high flexibility |

| 355mm(L)*155.8mm(W)*108.5mm(H) | ||

| Environmental Adaptability | High structural strength to meet harsh vehicle operating conditions and high-speed operation | Good vibration performance. For relatively large-sized banding modules, suggest using structural adhesive on the bottom to fix modules in assembly |

| Application Scene | Passenger cars, commercial vehicles | Commercial vehicles (bus, minicar, truck), Material handling equipment (Forklifts), Energy storage |

| Minimum Order Quantity | Without MOQ limit to the SOP frame welding modules. There are extra mold costs and MOQ requirements to custom frame welding modules | Without MOQ limit to banding modules |

Transition Your Energy to Sustainable Lithium-ion Batteries